The Foundry - Quality

ISO 9001:2015 Certified

We have set up this foundry with an aim to produce a high quality finished product. We currently manufacture various grades of grey cast iron as well as ductile iron. To achieve the quality our clients have come to expect, we have a solid infrastructure in place with the following facilities:

Our in house foundry lab is a world class facility capable of completely maintaining the chemical composition and physical properties of the material grade as required by the client. We currently produce FG200 & FG260 grade of grey cast iron and SG500/7 of Ductile iron. We currently have the following equipment in our lab:

We test a sample of all our material to ensure that the hardness is within specified limits.B

We currently have the following equipment to ensure quality of mould and core sand:

Sand Rammer, Sand Moisture, Permeability Meter, Mould Hardness Tester, Core Hardness Tester, Muffle Furnace, Universal Strength Machine, Sand Sieve Shaker, Electronic Balance, Methyl Blue Clay Tester, Compatibility Tester, Temperature Meter, B4 Cup Tester, Hot Plate

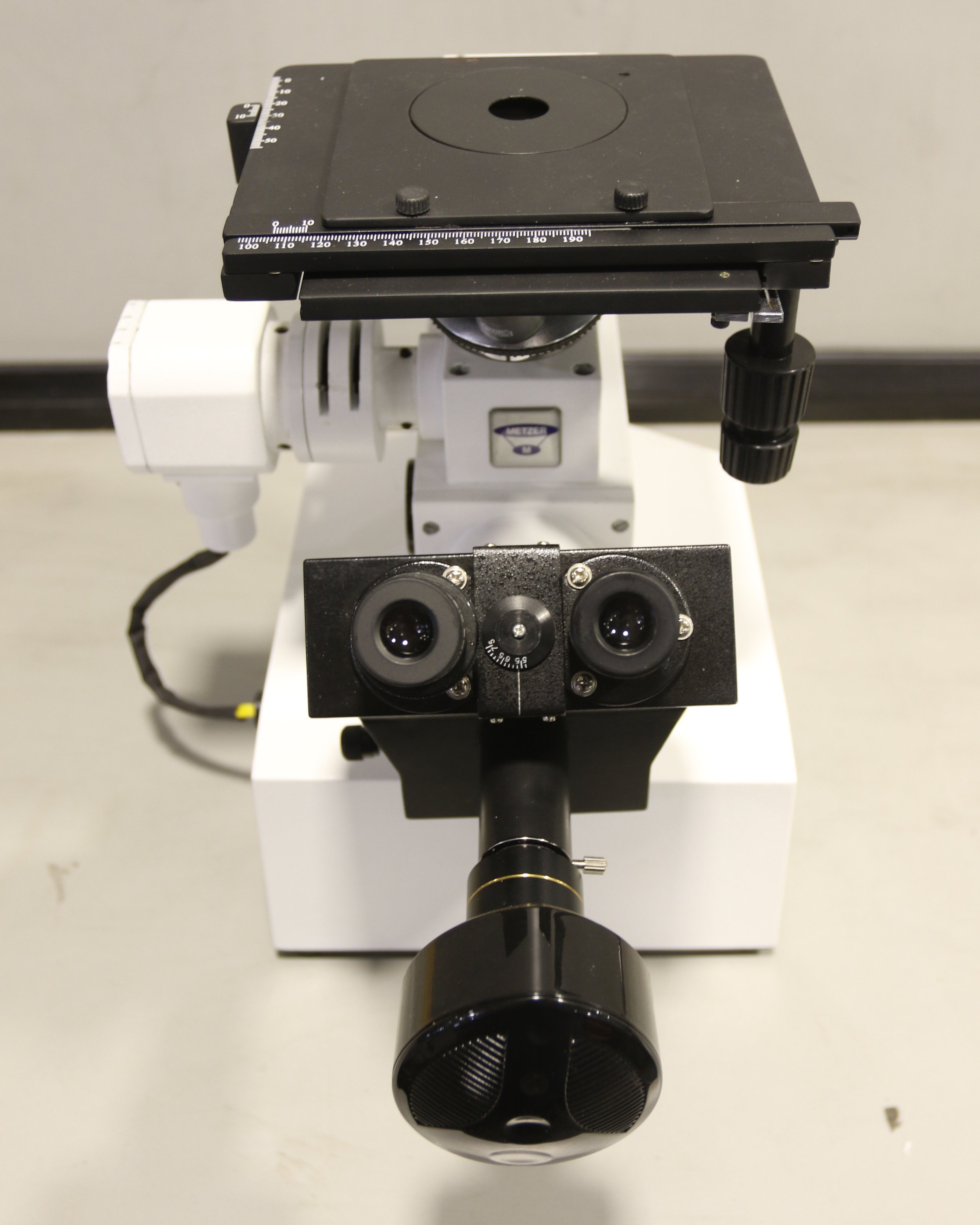

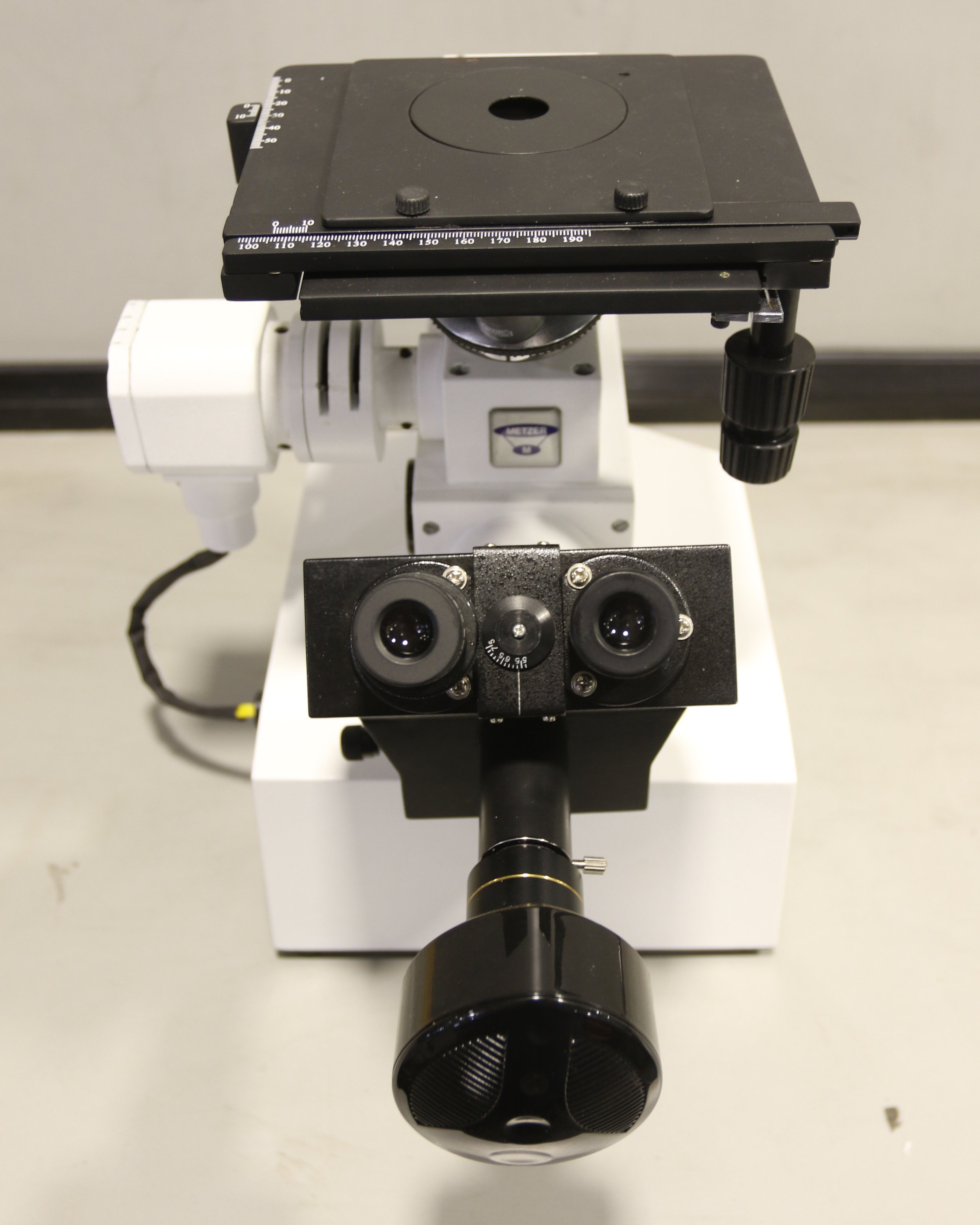

For SG iron we are required to analyse through a microscope to ensure that the nodularity parameter, ferrite parameter and pearlite parameter is achieved in the lot.

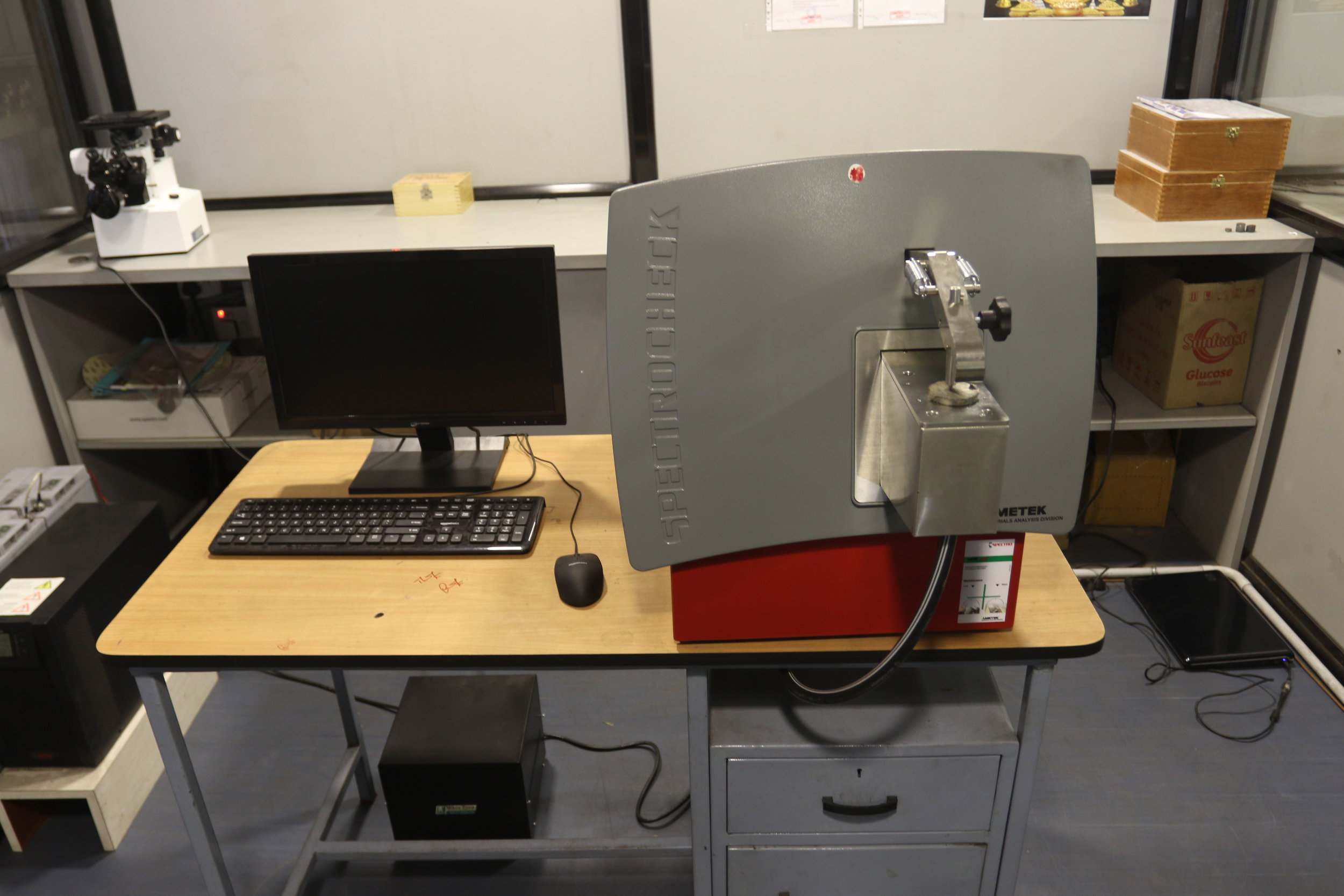

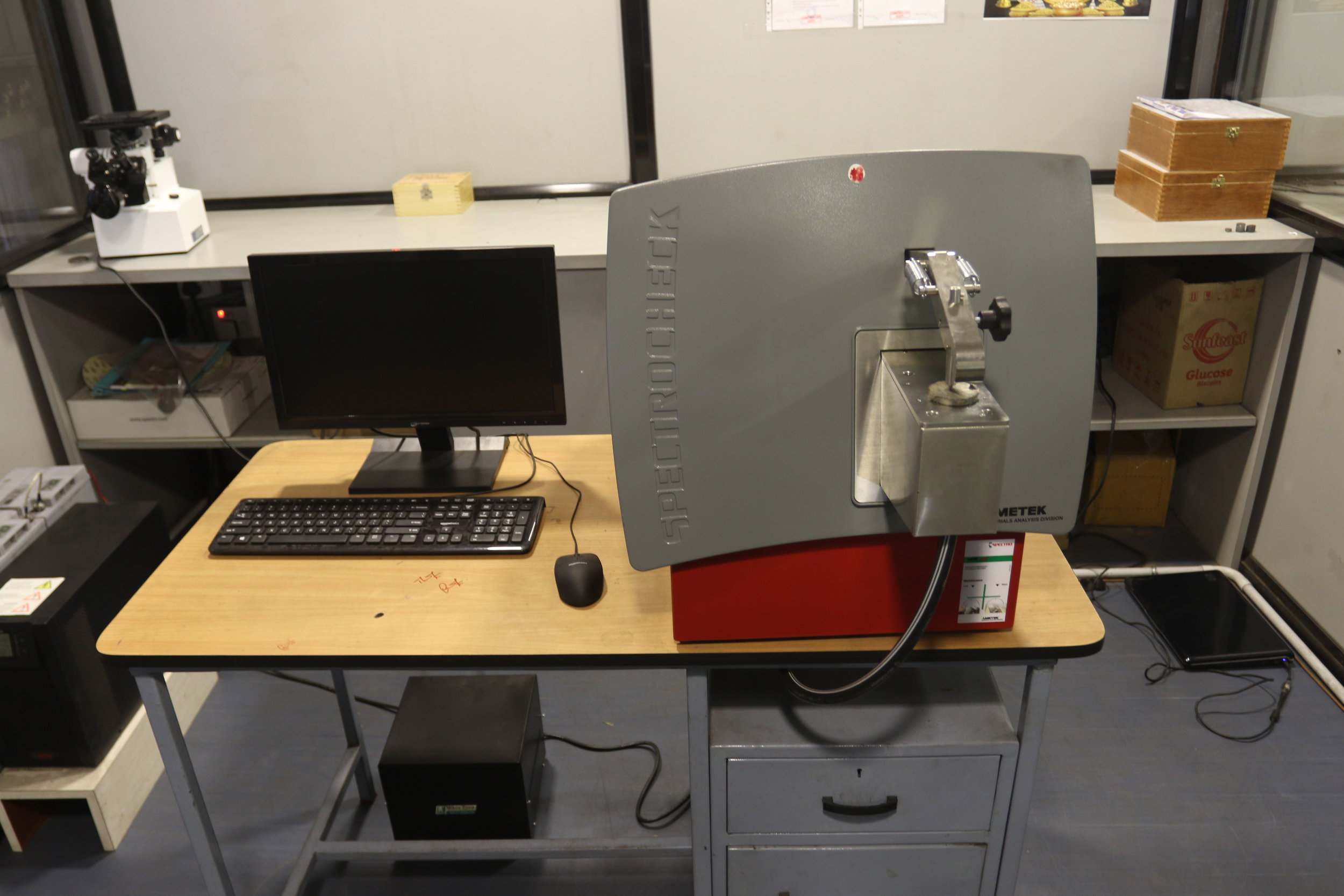

Capable of measuring upto 17 elements. Before each heat is poured, a sample coin is tested for composition. Only after the exact composition as per the required grade is achieved, do we proceed to pour the metal.

We have a 40 tonne capacity UTM to measure your component’s tensile strength.

While the metal is melting we use the CE meter to test the levels of carbon and silicon and add additives to tweak the composition of the metal. However final check is done only on the spectrometer to ensure high accuracy.

Constant monitoring of bath temperature as well as monitoring temperature while pouring ensures no rejections occur due to pouring of cold metal.